In the traditional procedure, a tray dryer is employed to achieve the optimum drying results.

Pharmaceutical Equipment:

Tray Dryer a brief introduction

The wet-granulation method is the most common and commonly utilised form of tablet manufacture. Its appeal stems from the fact that the granulation is more likely to meet all of the physical conditions for compressing good tablets. The number of individual steps involved, as well as the time and work required to carry out the procedure, especially on a big scale, are its main drawbacks. Weighing, mixing, wet massing, screening the damp mass, drying, dry screening, lubrication, and compression are the steps in the wet method.

The equipment required is determined by the batch size and the percentage of active ingredient in the total weight of the tablets.

- Low Shear mixers/granulators,

- High Shear mixers/granulators,

- Fluid-Bed granulators/Tray dryers,

- Spray Dryers, or

- Extruders and Spheronizers.

Dryers are used to evaporate or sublimate liquids or moisture from bulk solids, powders, components, continuous sheets, or other liquids. Direct and indirect dryers are the two most common types. Direct dryers heat a product by contacting it directly with heated air, gas, or a combusted gas product. Indirect dryers heat a product by conductive heating it against a heated wall.

In the traditional procedure, a tray dryer is employed to achieve the optimum drying results. It’s a two-door cabinet with a double-walled interior. To prevent heat transfer, the gap between two walls is filled with high density fibre glass wool insulation material. Gaskets are included with the doors. On the mobile carts, stainless steel trays are positioned. The Tray Dryer comes with a control panel board, a process timer, a digital temperature controller, and a cum indication, among other features. The Tray Dryer comes in capacities of 6, 12, 24, 48, 96, and 192 trays.

Tray Dryers Theory

A tray dryer is an enclosed insulated chamber where trays are stacked in trolleys on top of each other. Tray dryers are utilised in industries where heating and drying are critical aspects of the manufacturing process, such as chemicals, dyes, pharmaceuticals, food products, and colours. In the trays, moist or solid materials to be dried are inserted. Heat is transferred through the circulation of hot air generated by electric heaters or steam produced by radiator coils. Inside, blower fans are fitted to ensure appropriate heat circulation and transfer. Outside the dryer are a control panel for controlling the temperature and other parameters. These dryers come in a variety of materials, including mild steel, stainless steel, and wood.

Pigments, food, bread, electrodes, chemical, and plastic powders are all dried using a tray dryer. Electrically heated, steam heated, and thermic fluid heated drying ovens are often available.

A computerised temperature controller with a digital timer is included in the electrically heated type to make working day and night easier. Digital temperature indicator and digital timer are included in the steam and thermic fluid heated models, however, the temperature controller is not.

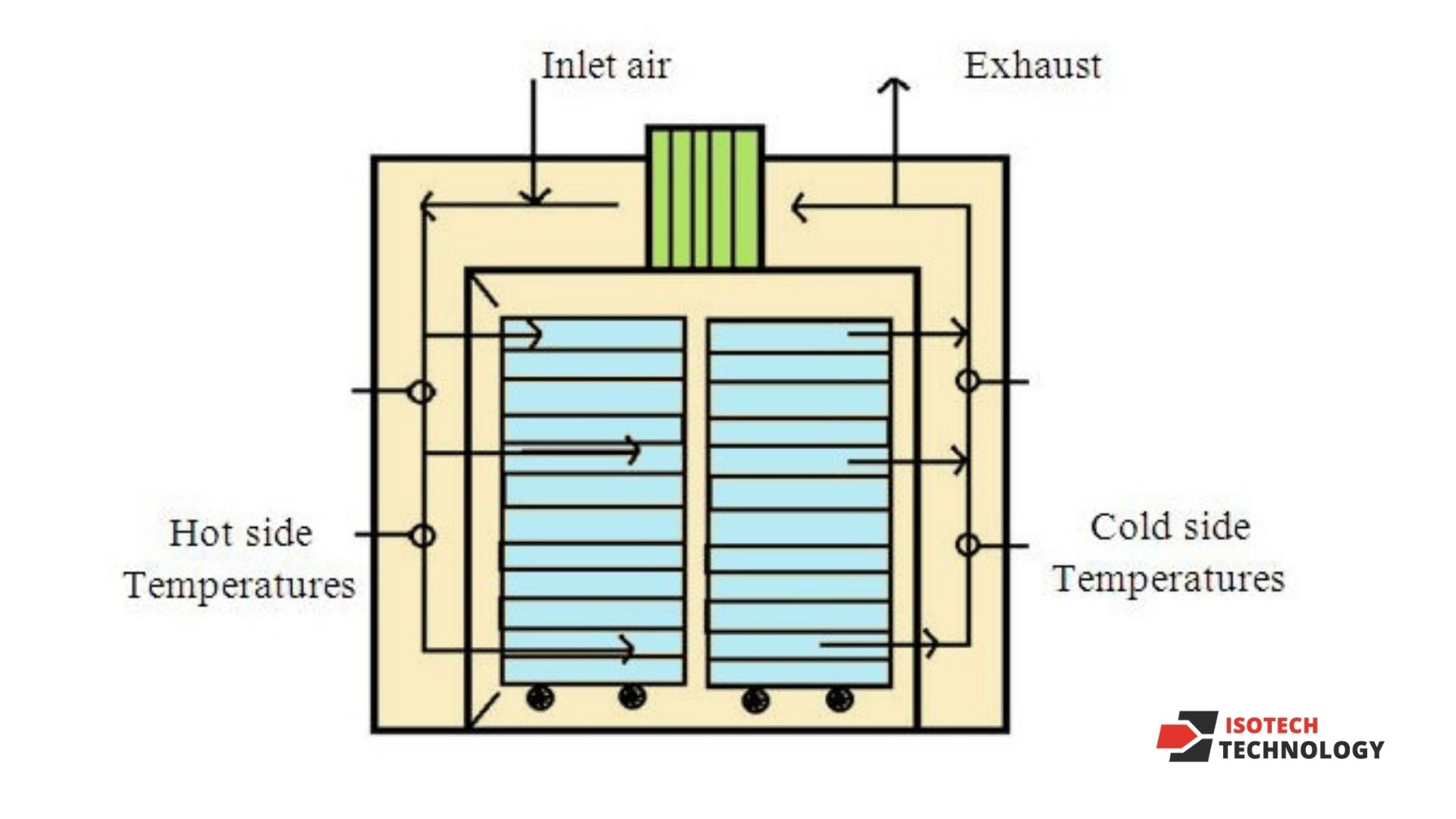

There is an extremely effective recirculating air system available. For maximum drying, warm air is recirculated with fresh air in specific amounts. The system is set up such that the materials on the top and bottom dry at the same time.

The oven’s assets include uniform air circulation, controlled temperature, durable construction, and a spacious working surface. It is designed to cover a wide temperature range, and loading and unloading is quick and easy. Tray trolleys roll into and out of the chamber at larger capacities. A spare trolley can be used to load while the drying cycle is running for continuous operation.

Working Principle of a Tray Dryer

Hot air is constantly pumped in the tray drier. To eliminate moisture from solids placed in trays, forced convection heating is used.

Simultaneously, the wet air is partially evacuated.

The trays are loaded with wet solids. In the chamber, trays are set.

Fresh air is delivered through an inlet and heated up as it travels past the heaters.

Fans circulate the heated air at a rate of 2 to 5 metres per second.

Turbulent flow diminishes the thickness of the air boundary layer and lowers the partial vapour pressure in the atmosphere.

The water is carried away by the wind. Water diffuses from the core of the solids as it evaporates from the surface due to capillary action.

These events happen in a single air pass. The contact time is short, and the amount of water collected in a single pass is minimal.

As a result, 80 to 90 percent of the discharged air is recirculated through the fans. Fresh air is only introduced about 10 to 20% of the time.

The outlet is used to release moist air. For consistent drying, a constant temperature and uniform air flow across the materials can be maintained.

In the case of wet granules, such as those found in tablets and capsules, drying is halted until the necessary moisture content is achieved.

At the end of the drying trays or trucks are pulled out of the chamber and taken to a tray dumping station.

Tray Dryer Construction & Specifications: The Tray Dryer should be built on formed angles of 3mm+ thick sheet and reinforced with angles and sections.

External walls of the dryer should be made of 1.6mm thick Stainless Steel sheets of 304 grade or higher.

The dryer’s inside is made up of 1.6 mm thick quality sheets. The internal structure should be completely TIG welded, and all interior surfaces should be ground smooth.

It should be clad with S,S, Polished sheets and insulated with a minimum of 50 mm thick glasswool insulation.

We deal with

Environmental Simulation Products

BOD Incubator

Cold Chamber

De Humidifier

Deep Freezers

Dust Chambers

Growth Chambers

Hot and Cold Chambers

Hot air Oven Chambers

Humidity Chambers

Reach in Growth Chambers

Salt Spray Chambers

Solar Chambers

Stability Chambers

Thermal Shock Chambers

Tray Dryer

Walk-in Cold Chambers

Walkin Environmental Chambers

Walkin Hot and Cold Chamber

Water Heated Jacket Oven

Leave a Reply