About Isotech

We provide top Industrial Services

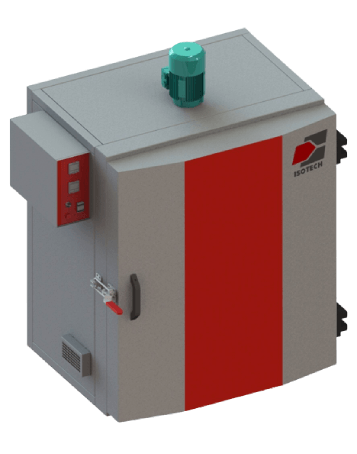

Isotechpl is leading Environmental Chamber Manufacturers and exporting company for Environmental Test Chamber, Scientific Instruments with specialization in all the Sectors with all the necessary Standards having accuracy just equivalent to Imported Calibration Instruments, resulting in import substitute for Indian users.

Innovative Technology

Innovative committed to technology & service Innovation.

Up-to-Date Market

In environmental chamber

The company ensures maximum satisfaction both in Quality and Product up-gradation of environmental chambers, maintaining the highest industry standards.

Know More

Years of Working Experience in this field.

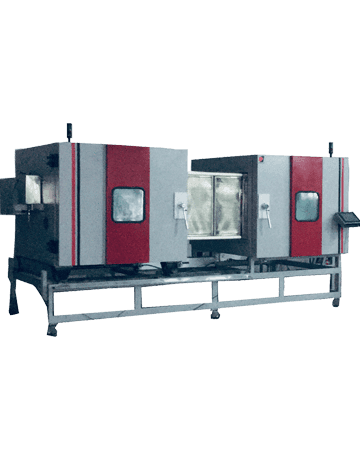

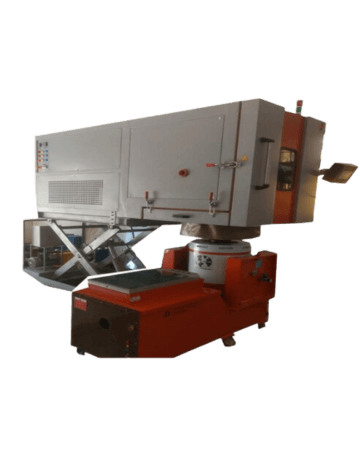

Isotech Manufacturing & Test Chamber Suppliers

Environmental Test Chambers

Our Applications

Isotech Technology Pvt Ltd. Bangalore, India. Environmental simulation industry to provide a comprehensive various range of products and services to the environmental test industry for various applications.

01

Aerospace Industry

Weather space shuttles, airplanes or helicopters & also Aerospace vessels are subjected to extreme situations. These range from extreme Changes in temperature up to vacuum states in outer space.

Read More02

Automotive Testing

The automotive industry is one of the most innovative industries today. The very highest standards are set in the manufacture and quality assurance of automobiles and automobile components.

Read More03

Agriculture/Science Industry

Biological research highly relies on controlled climatic conditions and the exact simulation of environmental conditions in many disciplines.

Read More04

Defence Testing

The Defence industry is one of the most innovative industries today. The very highest standards are set in the manufacture & quality assurance of automobiles & automobile components.

Read MoreIsotech Blog Posts

Industry to provide a comprehensive various range of products and services to the environmental test industry.

Humidity Test Chamber in Bangalore

Temperature Test Chamber in Bangalore

Power distribution panel manufacturer

Isotech Values

We always Dedicated for best solutions

Innovative Technology

Innovative Committed to Technology & Service Innovation.

Career Opportunities

Promising to offer our employees career opportunities for future.

Up-to-Date Market

Responsive to respond to changing market requirements.

Secure & Quality

Reliable to provide secure & qulity test solution.

Testimonials

ISOTECHPL Clients Review

Industry to provide a comprehensive various range of products and services to the environmental test industry.

I have been using Isotech environmental chambers for more than 3-4 years and placed order multiple times. The technology is robust, good product, user friendly and good technical support team. I highly recommend their products.

Radha Krishna

The Salt Spray Chamber product was of high quality, and the customer service was excellent. Overall, I am very happy with Environment Test Chamberand would highly recommend it to others.

Sanjeev Shetty

Nice working environment….Best Test Chamber Manufacturers from Bangalore.

Lokanath

Isotech Technology supplied a Reliability / Durability / Quality products to test the different Environmental testing.

Malcom Roy

I have been using Isotech environmental chambers for more than 3-4 years and placed order multiple times. The technology is robust, good product, user friendly and good technical support team. I highly recommend their products.

Radha Krishna

The Salt Spray Chambers product was of high quality, and the customer service was excellent. Overall, I am very happy with the product and would highly recommend it to others.

Sanjeev Shetty

Nice working environment….Best Environmental testing chamber manufactures from Bangalore.

Lokanath

Isotech Technology supplied a Reliability / Durability / Quality products to test the different Environmental testing.

Malcom Roy

ISOTECHPL