Humidity, Temperature, Heating, Cooling, Illumination, Co2, UV system.

Chambers Overview

Introduction to Reach In Growth Chamber

It is constructed in compliance with customer application.

Reach In Growth Chamber is intended for performing different type of test where the temperature and humidity of sample environment must be controlled within certain limits. The role of environment testing into examine and prove the suitability, reliability, durability of products through the exposure to the environmental effects of temperature, humidity, light, Co2, UV…e.t.c.

Acceleration of the environmental effects that these products will experience in nature is required is intended for performing different type of test where the temperature and humidity with illumination, Co2, UV, of sample environment must be controlled within certain limits. Our policy of continual liaison with leading researchers ensures we maintain our premier position as suppliers of high quality Reach In Plant Growth Chambers and associated facilities. Our Growth chamber were designed with Safety, Reliability, Ease of operating and ergonomically.

Main Features

- Test space dimensions are 3000 litres to 25000 litres.

- Temperature Range – 25° C to +80° C.

- Temperature deviation +/-0.5° C.

- Temperature Resolution 0.1° C.

- Temperature Gradient +/- 1° C to 2° C.

- Humidity Range 10 % RH to 97% RH.

- Humidity deviation 2% RH to 3% RH.

- Humidity Gradient +/- 3%.

Illumination system such a way that pre – selected programming control type. Light intensity regulation allows, users can select exactly the desired lighting level between approximately 10% to 100%. A very high lighting applications up to 100 micro moles/m2/sec to 1500 micro moles/m2/sec by using PAR light system. It is reducing heating effects on plants as well as related materials. Safety against any kind of accidental lamp breakage or electric shock. This provision is available only in ITRPYG models.

Carbon dioxide additive control Consisting system with sensor, Gas analyser system with Control valve, UV lights with sensor as well as safe protection system. Light meter provided for display and recording of light output. Programmable high and low temperature limits alarm automatically. This provision is available only in ITRPYG models.

Chambers Construction

Interior structure made of non frost vapour / air tight type. The high – gloss polished stainless steel test space is welded vapour tight, has well finished edges. it remains impervious to corrosion and easy to clean. Interior structure made of non frost vapour / air tight type. 16 Or 18 SWG 304 grade stainless Steel with adjustable / removable shelving. Outer external structure made of 16 Or 18 SWG CRCA /GI/ Stainless steel with electrostatic powder super fine coating finishing for a good appearance.

Insulation is environmentally friendly free of asbestos and CFC free mineral fiber insulation guarantees the best possible insulation values and hence, it will decrease the operating costs. Or CFC free Foamed in place Poly Urethane Foam (PUF) pre-fabricated. 80 mm puff panel insulation

Door hinges fitted on the right hand side of the chamber with front opening single door. Double lined ‘A’ grade silicon gasket on door as well as chamber body so that like proof tightens the door for better performance with multi pan glass viewing window. Defogger heaters provided with an auto cut – off as well as suitable illumination provided to view the specimen under test. Or flush mounted type door. Glass window for viewing inside. Positive cam lifts hardware. Safety release exit device for opening door from both the sides.

Performance

Air circulation within the chamber with suitable capacity of fan motor and impeller for uniform distribution of temperature and humidity to maintain within desired limits. High circulating air rates ensure even distribution of temperature and humidity. Only the impeller will be exposed in the conditioning plenum with drive motor from outside of the chamber. Condition plenum covered with a detachable type sheet for friendly maintenance of the chamber. Noise level is < 70db.

Quick responding jacket type air heaters are used for heating system to achieve the set value temperature. Highly uniform temperature distribution minimises variations in test results over multiple specimens. Air heaters are placed in such manner that, there is no direct heat radiation from the heaters on to the test specimen.

Direct vaporisation humidification system with low pressure steam vapour is used for stimulating the required humidity. Reservoir with automatic float switch for maintain at appropriate level for continuous water supply to the humidity tank.

A refrigeration based de-Humidification system provided for avoid the condensation forming on test specimen as well as control the lower relative humidity.

Water Cooled / Air-cooled mechanical type single stage non CFC mechanical compression type refrigeration system. Ozone friendly refrigerant with hermetically sealed / low power consumption high boosted semi sealed compressor provided and system is designed such a way that, safety protection against high / low pressure and temperature. Electronic auto expansion valve system for expansion mechanism. Water / Air cooled condenser. Plate fin type cooler. Refrigerant R404A. Pressure measuring device provided for measuring suction and head / discharge pressure of refrigeration systems. HP / LP cutoff / Oil separators with oil return system.

Instrumentation System

Programmable controller using large screen display. Instrumentation package features flexible. Other functions are included user friendly operation with TFT LCD touch screen as well as key input, graphical display of program patterns, testing history trend grapes. A no. of programs & profile segments with ramp & soak duration provided for cyclic operation.

The controller is able to communicate with many different types of hardware using high speed RS 232/485 communications ports, networking and USB communications for fast downloads. Power failure recovery operation system. Password proaction system.

Microprocessor PID non programmable controller for Temperature as well as Humidity in RE models.

P.T 100 sensor is measuring the temperature and high precision RH sensor for humidity measuring. The measuring method considerably improved by using of an continuously wetted humidity sensor and this type wetting effects the self cleaning procedure of the sensor and vastly improving the service life. Light intensity measuring sensor, Co2 Sensor.

Safety Devices

Reach In Growth Chamber equipped with an emergency stop switch. High reliability and operator safety. Easy protection of chamber and specimen in case of failure. Chambers stop if the door is opening as operator safety. European style design signal tower.

Control circuit over current protection. Thermal fuse. Adjustable adequate safety cut – out against high and low temperatures. Chamber door limit switch. Every electrical functional circuit is equipped its own safety facility which shuts down the functional circuit affected or the entire test chamber in case of a malfunction.

Model Number

Cable Port holes are located on the left or on the right side of the test chamber and shall be used for inserting measurement and control cables, other supply connections or additional equipment with rubber plug.

Standard specification shelves and shelf are added as required.

Drain out let pipe with suitable fittings.

Electrical connection 415 V AC +/- 10%, 3 phase/N/PE 50 Hz.

| Model No. | Temperature Range | Humidity Range | Test space dimensions in liters |

|---|---|---|---|

| ITRGC-25 RE | -25°C to +80°C | 20% to 97% | 3000 Liter to 25000 Liter |

| ITRGC-10 RE | -10°C to +80°C | 20% to 97% | 3000 Liter to 25000 Liter |

| ITRGH-10 RE | +10°C to +80°C | 20% to 97% | 3000 Liter to 25000 Liter |

| ITRGH–20 RE | +20°C to +80°C | 20% to 97% | 3000 Liter to 25000 Liter |

| ITRGC-25 LO | -25°C to +80°C | 20% to 97% | 3000 Liter to 25000 Liter |

| ITRGC-10 LO | -10°C to +80°C | 20% to 97% | 3000 Liter to 25000 Liter |

| ITRGH-10 LO | +10°C to +80°C | 20% to 97% | 3000 Liter to 25000 Liter |

| ITRGH-20 LO | +20°C to+ 80°C | 20% to 97% | 3000 Liter to 25000 Liter |

| ITRPYG-25 SP | -25°C to +80°C | 20% to 97% | 3000 Liter to 25000 Liter |

| ITRPYG-10 SP | -10°C to +100°C | 20% to 97% | 3000 Liter to 25000 Liter |

| ITRPYG-10 SP | +10°C to +100°C | 20% to 97% | 3000 Liter to 25000 Liter |

Note: LO = Logic programmable Models. RE = Non Programable Models. SP = Special Models.

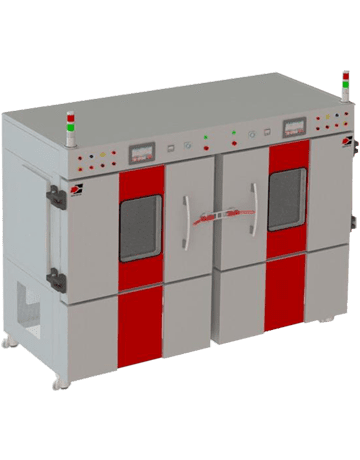

Our Reach In Growth Chamber Samples

Reach In Growth Chamber

Isotech Technologies

Reach In Growth Chamber

Isotech Technologies

Reach In Growth Chamber

Isotech Technologies

Reach In Growth Chamber

Isotech Technologies

Let’s Talk About your Requirements

Check with our team by submitting a simple form, Our team will get in touch with you soon..!

Call Us: (+91) 984-594-6739

ISOTECHPL

Frequently Asked Questions!

- Larger capacity for accommodating multiple experiments or larger plants

- Easier access to plants for observation and maintenance

- Ability to create a more uniform environment throughout the chamber

- Controlled CO2 injection for enhancing plant growth

- UV lighting for studying plant responses to ultraviolet radiation

- Temperature control ranging from -40°C to +60°C for simulating a wide range of environmental conditions

- Agricultural research: Studying the effects of different growing conditions on crop yields and quality

- Plant pathology: Investigating the effects of pathogens on plant health

- Environmental science: Assessing the impact of environmental pollutants on plants

- Education: Demonstrating plant growth processes to students

- Precise control of temperature, humidity, light, and CO2 levels

- Durable construction for years of reliable operation

- Easy-to-use controls and monitoring systems

- The size of the chamber: This will depend on the number of plants you need to grow and the available space in your laboratory or greenhouse.

- The type of plants you will be growing: Some plants require specific environmental conditions, such as high humidity or low light levels.

- The level of control you need over the environment: If you need to precisely control temperature, humidity, light, and CO2 levels, you will need a more sophisticated chamber.

- Cleaning the chamber regularly to prevent the buildup of mold and mildew

- Calibrating the chamber’s sensors to ensure accurate readings

- Checking for leaks and other signs of wear and tear

- Always wear gloves and safety glasses when handling chemicals or working with plants that may be harmful.

- Be aware of the potential for electrical hazards and take appropriate precautions.

- Do not overload the chamber with plants or equipment.

- Follow the manufacturer’s instructions for operating and maintaining the chamber.