Intended to simulate thermal cycling, humidity, UV exposure, freezing temperatures.

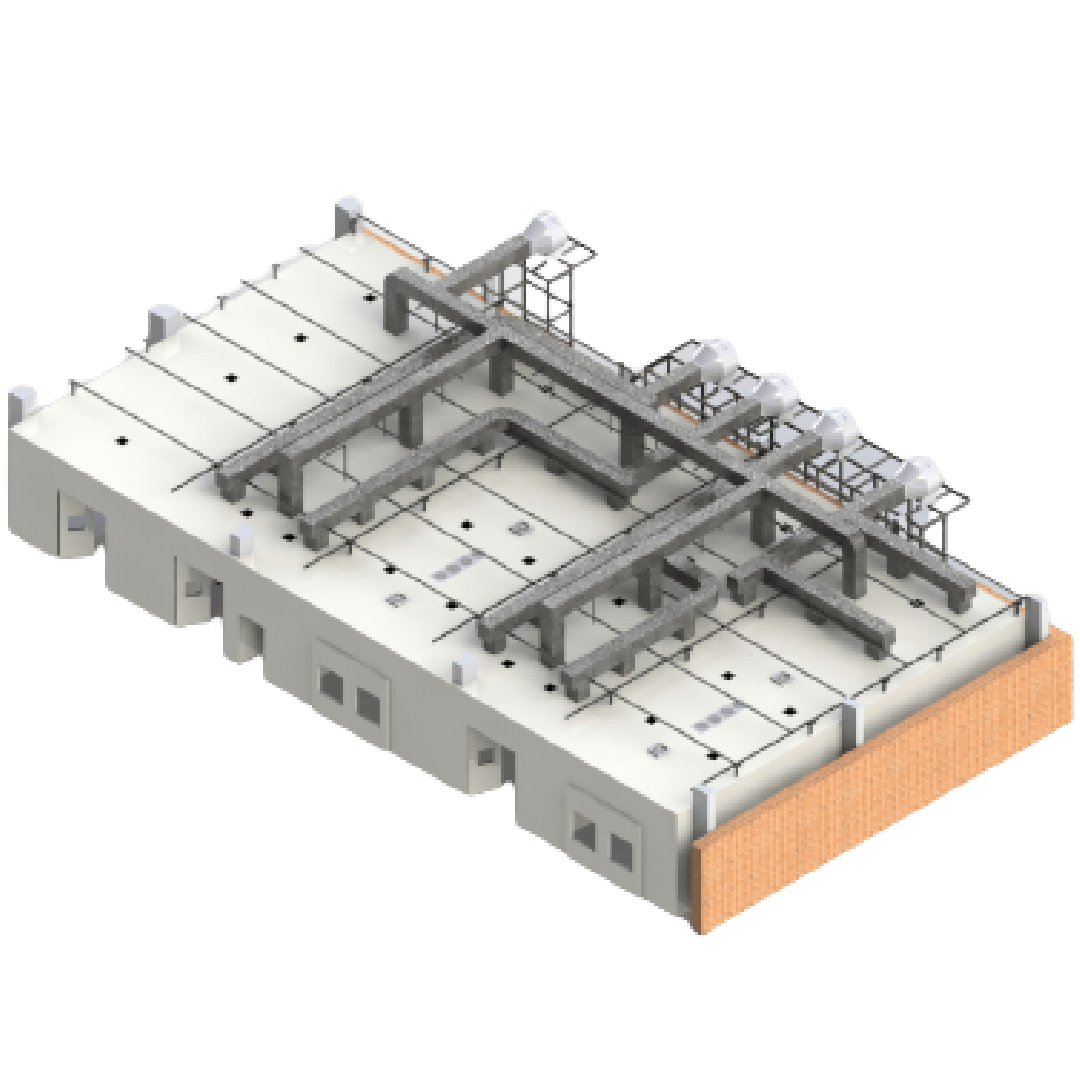

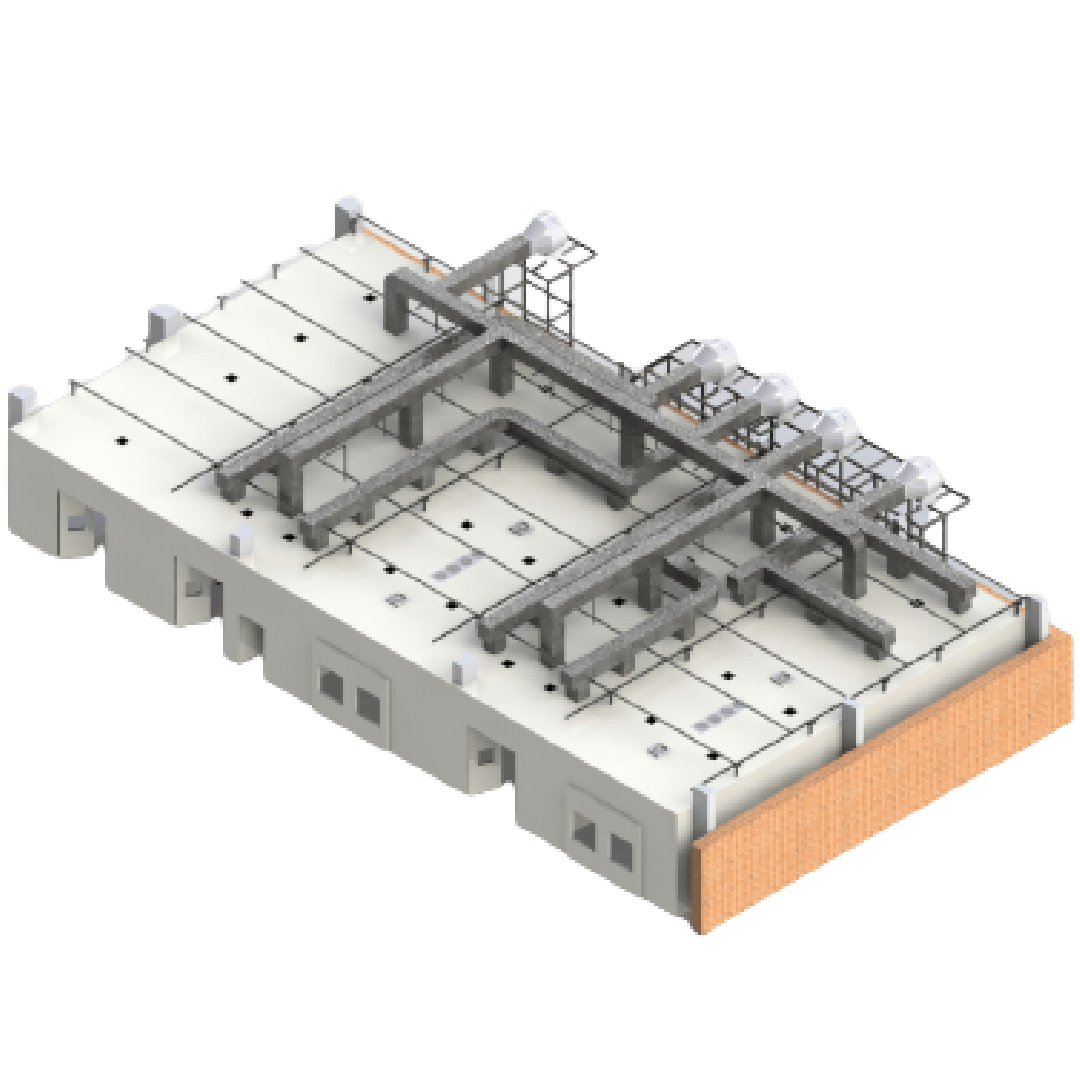

Chambers Overview

Introduction Burn-In Chamber

Physical inspection, certain components (capacitors, resistors, integrated circuits)

Inverter testing is an exhaustive process. Prior to assembly each component should be individually inspected for quality. In addition to a visual and physical inspection, certain components (capacitors, resistors, integrated circuits) may be x-rayed to confirm that no manufacturing defects are hidden within. For a truly reliable inverter, however, quality begins at the design table.

The first step inverter manufacturers should undertake is the minimization of parts prone to failure. This routinely includes fans and LCD screens. Over time the motors in fans burn out and LCD screen routinely fail after years exposed to the elements.

Main Features

Reliability Test

- Verification of potential causes based upon DFMEA

- Subassembly ALT, Thermal, Thermal Cycle

- Environmental Testing – Temp/Humidity, Salt Fog

- HALT

- System Level ALT.

Accelerated Testing Applied to PV Inverters

- Accelerated Life Testing

- Temperature

- Humidity, Temperature-Humidity

- Voltage

- Temperature Cycling

- Power Cycling

- Highly Accelerated Life Testing

- Cold step stressing

- Hot step stressing

- Rapid thermal transitions

- Vibration step stressing

- Combined environments.

Highly Accelerated Life Test – HALT

- HALT is intended to uncover design and design margin issues

- Five stresses

- Cold step stressing

- Hot step stressing

- Rapid thermal transitions

- Vibration step stressing

- Combined environments in addition to maximum loading the inverters are exercised under power

- Corrective Actions

- Achievement of acceptable design margins.

- Temperature margins, Vibration margins, Combined stresses

Chambers Construction

Once a robust design is in place and inverters begin rolling off the production line, quality control testing should be done to ensure reliability and performance and to simulate real-life exposure. Testing facilities are home to a spectrum of environmental chambers intended to simulate thermal cycling, humidity, UV exposure, freezing temperatures, exposure to marine conditions and extreme vibration.

Accelerated testing is an efficient strategy to improve reliability for commercial and utility photovoltaic Grid inverter equipment. The two most often used tests are highly accelerated life testing (HALT) and accelerated life testing (ALT).

HALT is a technique that yields results within a few days due to the nature of the acceleration factors used in the test whereby the unit is subjected to progressively higher stress levels and the inclusion of combined temperature and vibration. HALT is an invaluable method to uncover design weaknesses and is used at both the system as well as assembly level.

Performance

Accelerated Life Testing (ALT) is useful to determine wear-out mechanisms or lifetime within confidence limits. ALT is capable of determination for product reliability in a short time period of weeks or months by environmental acceleration factors.

ALT can find dominant failure mechanisms and is a valuable tool for the discovery of wear-out failure. In addition, ALT methods can serve as qualification criteria to prescribed lifetime confidence limits.

ALT at the system level involves integration of multiple units such as an inverter and power supply within a large environmentally controlled facility.

Subsystem life testing can be completed within smaller environmental enclosures or may be accomplished as a component integrated within the inverter at the unit or system level testing facility.

Instrumentation System

For ALT, the acceleration factor, length of the test, number of samples, confidence required, and test environment are known.

The most common temperature acceleration factor is based upon the Arrhenius model. For PV Grid inverters another acceleration factor is the duty cycle whereby testing may be accomplished continually as opposed to the sun-cycle restrictions for on-site exposure.

Safety Devices

In addition, inclusion of solar simulation methods provides for inverter cycling experienced during environmental and solar resource extremes. One element of efficient ALT qualification is envelope performance testing at environmental extremes. Insight into wear-out lifetimes.

Once, it has been determined that the inverter design can attain expected lifetimes, burn-in procedures are developed and used to ensure that the product does not contain process or assembly defects.

Model Number

| Model No. | Temperature Range | Test space dimensions in liters. |

|---|---|---|

| ITBIC – 60 LO | RT+10 °C to +60° C | 2500 Liter to 850000 Liter |

| ITBIC – 100 LO | RT+10 °C to+ 100° C | 2500 Liter to 850000 Liter |

Note: LO = Logic programmable Models.

Our Burn-In Chamber Samples

Burn-In Chamber

Isotech Technologies

Burn-In Chamber

Isotech Technologies

Burn-In Chamber

Isotech Technologies

Burn-In Chamber

Isotech Technologies

Let’s Talk About your Requirements

Check with our team by submitting a simple form, Our team will get in touch with you soon..!

Call Us: (+91) 984-594-6739

ISOTECHPL

Frequently Asked Questions!

- Increased product reliability

- Reduced warranty costs

- Improved customer satisfaction

- Semiconductors

- Printed circuit boards (PCBs)

- Electronic assemblies

- Medical devices

- Aerospace components

- Static burn-in chambers

- Dynamic burn-in chambers

- Precise temperature and humidity control

- Programmable test parameters

- Remote monitoring and control

- Data logging capabilities

- Unmatched reliability and performance

- Wide range of testing capabilities

- User-friendly interface

- Comprehensive data logging