In order to track the fast paced battery and EV development.

Chambers Overview

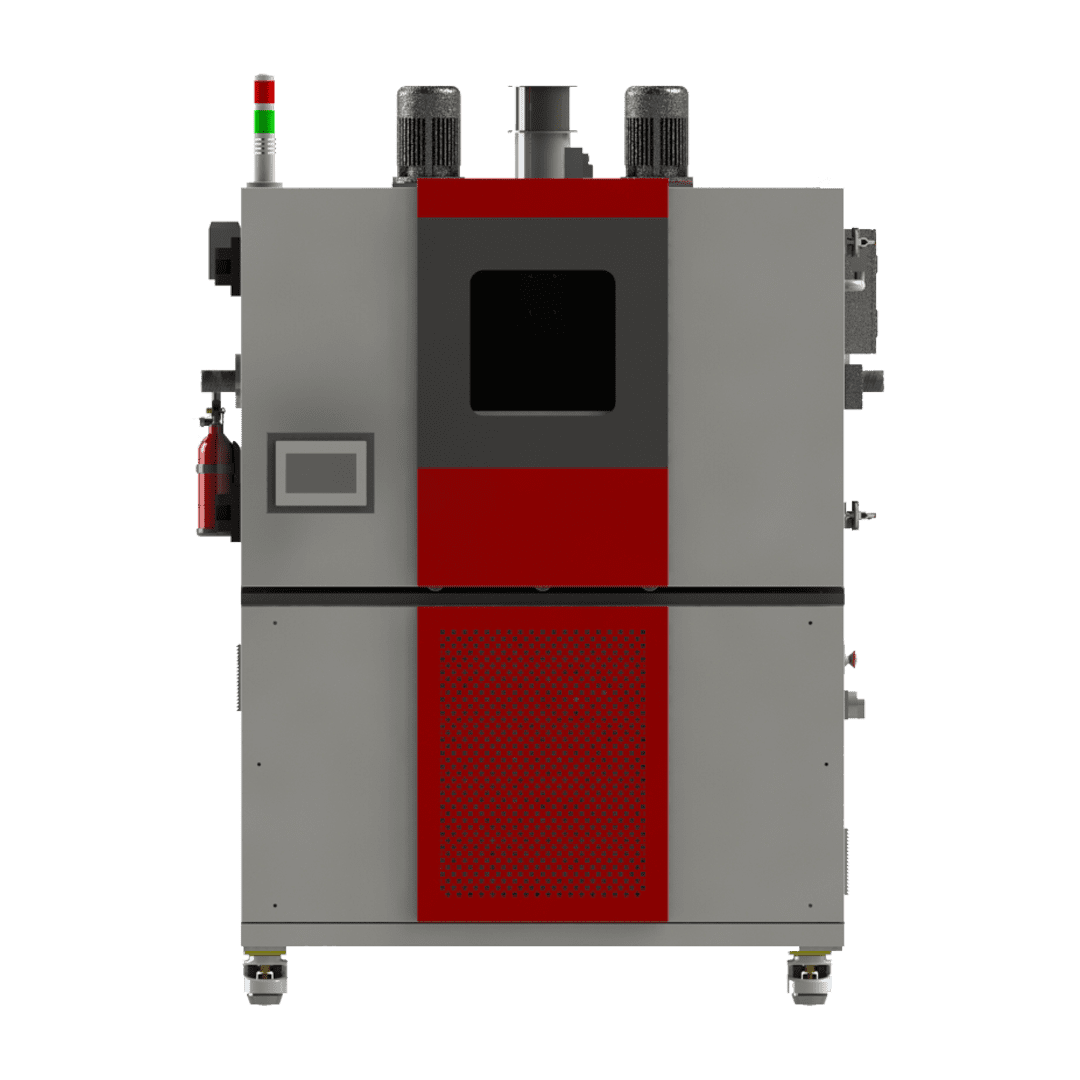

Introduction Battery Testing Chamber

Battery Requirements 2030 (Version 2019)

The purpose of this document is to provide an automotive perspective on the requirement targets for the main traction battery in BEVs and (Plug in Hybrid Electric Vehicle) PHEVs by the year 2030. Based on today’s understanding of the state of art of battery technologies and their applications and forecasting their development into the next decade, the expert group has set challenging targets for battery requirements.

These targets are meant to be used as values that can guide researchers, policy makers and other interested parties towards setting goals that can be realistically achieved in the mentioned timeframe.

Main Features

The Battery Targets 2030 proposes values for relevant characteristics of battery cells and battery pack. These values may differ depending on the applications, vehicle segment and driving range. This version will cover for BEVs 3 case,

- Passenger cars with low range (~400 km)

- High range (>600 km)

- Commercial heavy-duty vehicles (CV HDV)

For PHEV type, there are 3 cases,

- Passenger car (e-range ~100 km)

- Distribution truck (e-range ~70 km)

- Long-haul commercial vehicle (e-range ~150 km)

General Battery Description

A battery is an energy storage system used in automotive application to supply power (watts) to electronic equipment. Battery system is made up of number of cells connected in series or parallel to provide the needed power and energy for the targeted application.

Each cell consists of two electrodes which can store the electric charge carriers. In charging mode, the charge carriers are brought to one electrode via external charging source under application of high voltage on the cell. When a charged cell is connected to an electrical device, electrons can flow through this external circuit to run an electric device, e.g. an electric machine.

Performance

This process depletes the charge carrier from the anode, which can be observed by the drop-in voltage. The cell is completely discharged when its permissible lower voltage is reached, after which it needs to be charged again before reuse. The operational voltage window of a cell is determined by the types of materials within the electrodes used and this allows the cell to charge and discharge within this voltage range in repetition.

Air-cooled mechanical type single stage non CFC mechanical compression type refrigeration system. Ozone friendly refrigerant with hermetically sealed compressor provided and system is designed such a way that, safety protection against high / low pressure and temperature. Electronic auto expansion valve system for expansion mechanism. Air cooled condenser. Plate fin type cooler. Refrigerant R- 134 a Or R404A. Pressure measuring device provided for measuring suction and head / discharge pressure of refrigeration systems.

HP / LP cutoff / Oil separators with oil return system.

Instrumentation System

Programmable controller using large screen display. Instrumentation package features flexible. Other functions are included user friendly operation with TFT LCD touch screen as well as key input, graphical display of program patterns, testing history trend grapes. A no. of programs & profile segments with ramp & soak duration provided for cyclic operation. The controller is able to communicate with many different types of hardware using high speed RS 232/485 communications ports, networking and USB communications for fast downloads. Power failure recovery operation system.

Microprocessor PID non programable controller for RE models. P.T 100 sensors to measuring the temperature

P.T 100 sensors to measuring the temperature.

Safety Devices

BTC Incubator equipped with an emergency stop switch. High reliability and operator safety. Easy protection of chamber and specimen in case of failure. Chambers stop if the door is opening as operator safety. European style design signal tower.

Control circuit over current protection. Thermal fuse. Adjustable adequate safety cut – out against high and low temperatures. Chamber door limit switch. Every electrical functional circuit is equipped its own safety facility which shuts down the functional circuit affected or the entire test chamber in case of a malfunction.

Model Number

Cable Port holes are located on the left or on the right side of the test chamber and shall be used for inserting measurement and control cables, other supply connections or additional equipment with rubber plug.

Standard specification shelves and shelf are added as required. Drain out let pipe with suitable fittings.Electrical connection 230 V AC +/- 10%, 1 phase/N/PE 50 Hz.

| Model No. | Size/Volume | Temperature Range | Heating and Cooling Rate |

|---|---|---|---|

| ITBTEC -70 LO | 400 Litres to 1500 Litres | -70°C to +200°C with humidity range from 10% to 98% | 3°C to 5°C |

| ITBTEC -40 LO | 400 Litres to 1500 Litres | -40°C to +150°C with humidity range from 10% to 98% | 3°C to 5°C |

Note: LO = Logic programmable Models.

Application: Automobiles Industries / Battery Manufacturing Industries/ EV vehicle Industries / Power Bank Manufacturing Industries.

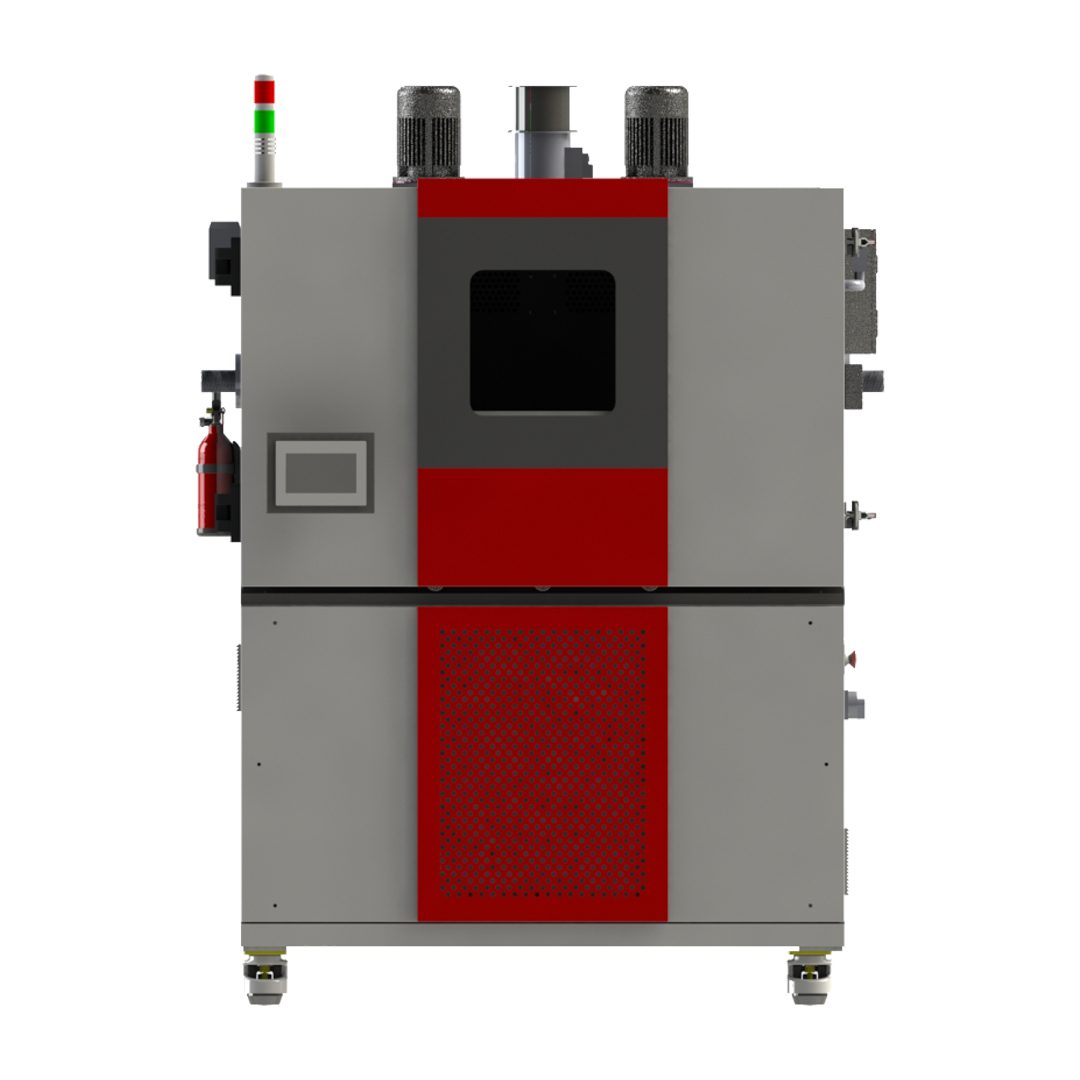

Our Battery Testing Chamber Samples

Battery Testing Chamber

Isotech Technologies

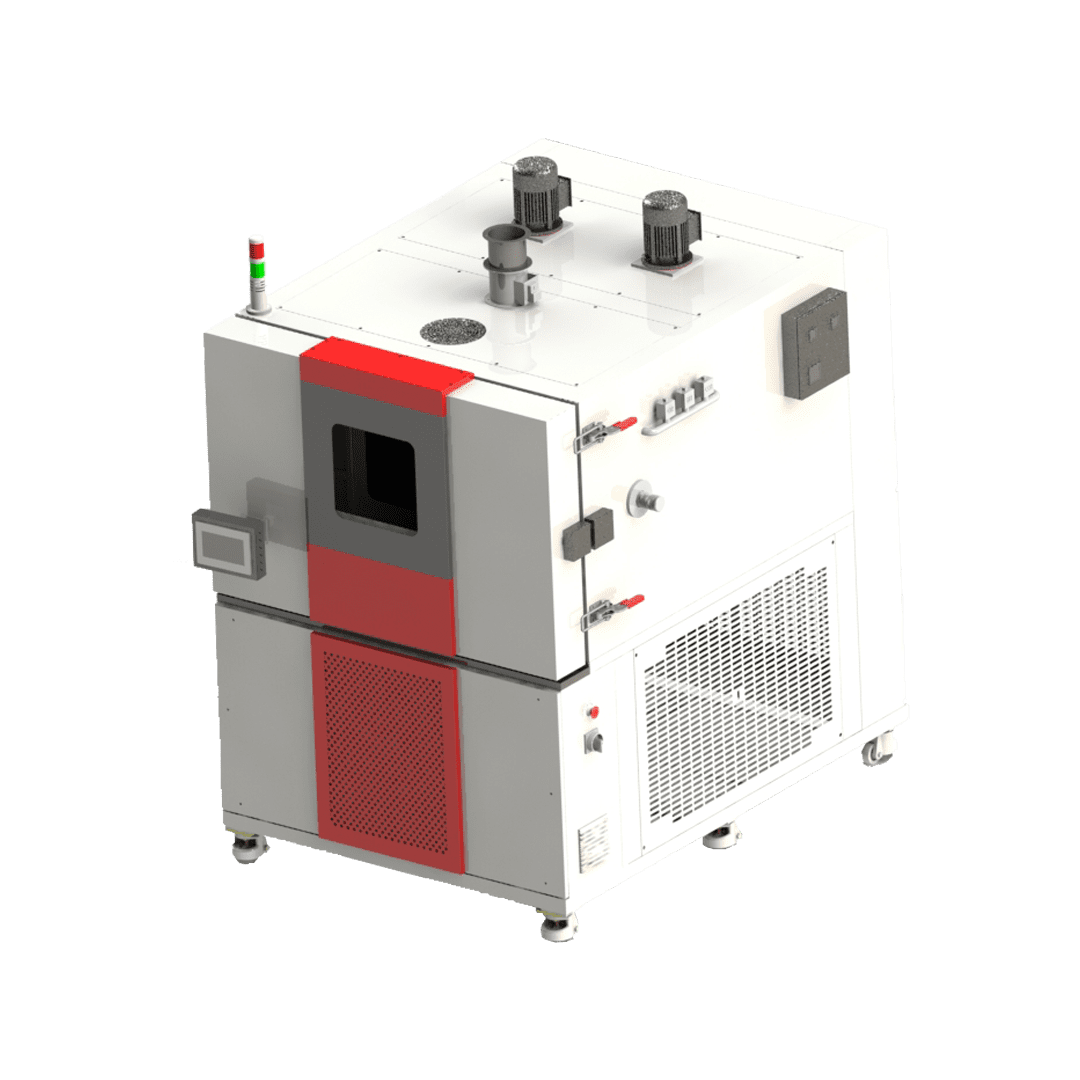

Battery Testing Chamber

Isotech Technologies

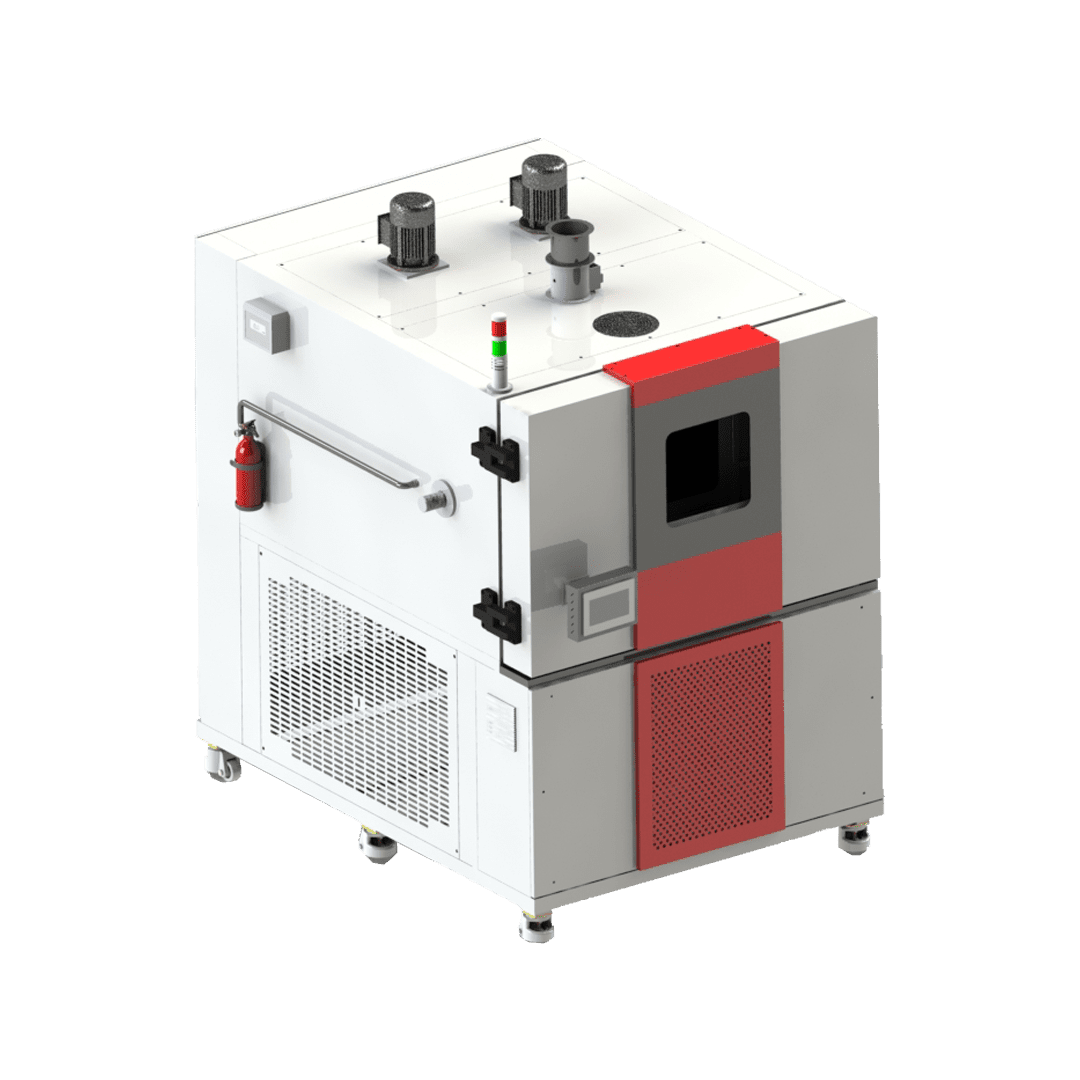

Battery Testing Chamber

Isotech Technologies

Battery Testing Chamber

Isotech Technologies

Let’s Talk About your Requirements

Check with our team by submitting a simple form, Our team will get in touch with you soon..!

Call Us: (+91) 984-594-6739

ISOTECHPL