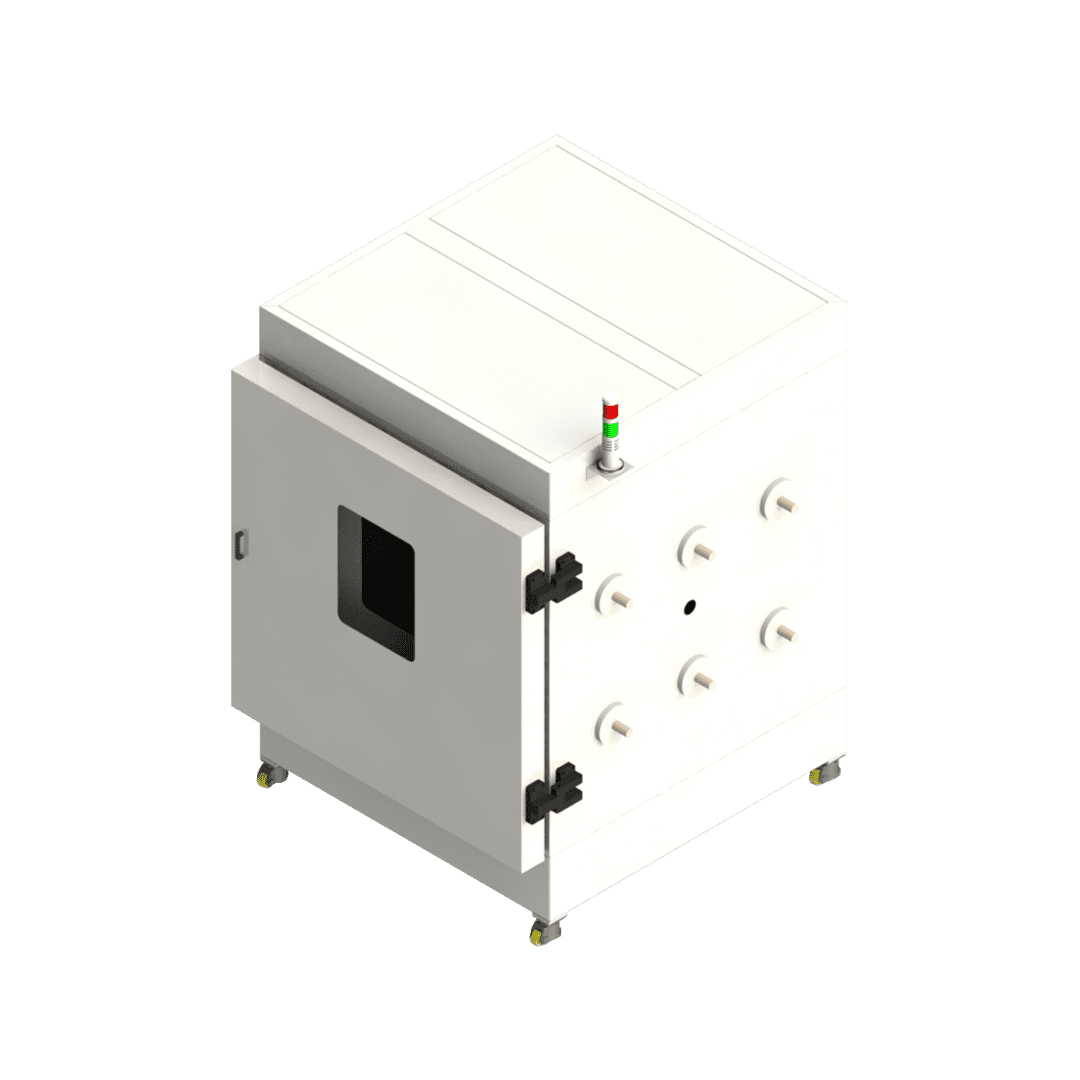

Hot Air Oven. Temperature, Heating.

Introduction

Digital Laboratory Hot Air Oven

It is constructed in compliance with ASTM, IEC, IS, IS 9000.

Laboratory Hot Air Oven is intended for performing different type of test where the temperature of sample environment must be controlled within certain limits. Our policy of continual liaison with leading researchers ensures we maintain our premier position as suppliers of high quality Hot Air Oven and associated facilities. Our Hot Air Drying Oven, were designed with Safety, Reliability, Ease of operating and ergonomically.

Main Features

- Test space dimensions are 100 litres to 20000 litres.

- Temperature Range RT +5° C to +300° C.

- Temperature deviation +/-1° C.

- Temperature Resolution 0.1° C.

- Temperature Gradient +/- 1° C to 2° C.

- Average Temperature Raise/Fall 1° C to 10° C.

Chambers Construction

Interior structure made of air tight type. 16 Or 18 SWG 304 grade stainless Steel with adjustable / removable shelving. Outer external structure made of 16 Or 18 SWG CRCA /GI/ Stainless steel with electrostatic powder super fine coating finishing for a good appearance.

Insulation is environmentally friendly free of asbestos and CFC free mineral fiber insulation guarantees the best possible insulation values and hence, it will decrease the operating costs.

Door hinges fitted on the right hand side of the chamber with front opening single door. Double lined ‘A’ grade silicon gasket on door as well as chamber body so that like proof tightens the door for better performance with multi pan glass viewing window. Defogger heaters provided with an auto cut – off as well as suitable illumination provided to view the specimen under test.

Performance

Air circulation within the chamber with suitable capacity of fan motor and impeller for uniform distribution of temperature and humidity to maintain within desired limits. Only the impeller will be exposed in the conditioning plenum with drive motor from outside of the chamber. Condition plenum covered with a detachable type sheet for friendly maintenance of the chamber. Noise level is < 70db.

Quick responding jacket type air heaters are used for heating system to achieve the set value temperature. Highly uniform temperature distribution minimises variations in test results over multiple specimens. Air heaters are placed in such manner that, there is no direct heat radiation from the heaters on to the test specimen.

Instrumentation System

Programmable controller using large screen display. Instrumentation package features flexible. Other functions are included user friendly operation with TFT LCD touch screen as well as key input, graphical display of program patterns, testing history trend grapes. A no. of programs & profile segments with ramp & soak duration provided for cyclic operation.

The controller is able to communicate with many different types of hardware using high speed RS 232/485 communications ports, networking and USB communications for fast downloads. Power failure recovery operation system.

Microprocessor PID non programmable controller for Temperature in RE models.

P.T 100 sensor is measuring the temperature.

Safety Devices

Hot Air Oven equipped with an emergency stop switch. High reliability and operator safety. Easy protection of chamber and specimen in case of failure. Chambers stop if the door is opening as operator safety. European style design signal tower.

Control circuit over current protection. Thermal fuse. Adjustable adequate safety cut – out against high and low temperatures. Chamber door limit switch. Every electrical functional circuit is equipped its own safety facility which shuts down the functional circuit affected or the entire test chamber in case of a malfunction.

Model Number

Cable Port holes are located on the left or on the right side of the test chamber and shall be used for inserting measurement and control cables, other supply connections or additional equipment with rubber plug.

Standard specification shelves and shelf are added as required.

Drain out let pipe with suitable fittings.

Electrical connection 415 V AC +/- 10%, 3 phase/N/PE 50 Hz. 230 V AC +/-10%, 1 phase

| Model No. | Temperature Range | Test space dimensions in liters |

|---|---|---|

| ITHAO – 300 LO | RT +5° C to + 300° C | 125 liters to 20000 liters |

| ITHAO – 200 LO | RT+5° C to + 200° C | 100 liters to 20000 liters |

| ITHTC–100 LO | RT +5°C to +100°C | 100 liters to 20000 liters |

Note: LO = Logic programmable models. RE= Non programmable models.

Our Hot Air Oven Samples

Hot Air Oven

Isotech Technologies

Hot Air Oven

Isotech Technologies

Hot Air Oven

Isotech Technologies

Hot Air Oven

Isotech Technologies

Let’s Talk About your Requirements

Check with our team by submitting a simple form, Our team will get in touch with you soon..!

Call Us: (+91) 984-594-6739

Testimonials

ISOTECHPL Clients Review

Industry to provide a comprehensive various range of products and services to the environmental test industry.

I have been using Isotech environmental chambers for more than 3-4 years and placed order multiple times. The technology is robust, good product, user friendly and good technical support team. I highly recommend their products.

Radha Krishna

The Salt Spray Chambers product was of high quality, and the customer service was excellent. Overall, I am very happy with the product and would highly recommend it to others.

Sanjeev Shetty

Nice working environment….Best Environmental testing chamber manufactures from Bangalore.

Lokanath

Isotech Technology supplied a Reliability / Durability / Quality products to test the different Environmental testing.

Malcom Roy

I have been using Isotech environmental chambers for more than 3-4 years and placed order multiple times. The technology is robust, good product, user friendly and good technical support team. I highly recommend their products.

Radha Krishna

The Salt Spray Chambers product was of high quality, and the customer service was excellent. Overall, I am very happy with the product and would highly recommend it to others.

Sanjeev Shetty

Nice working environment….Best Environmental testing chamber manufactures from Bangalore.

Lokanath

Isotech Technology supplied a Reliability / Durability / Quality products to test the different Environmental testing.

Malcom Roy

Other Environmental Test Chambers

ISOTECHPL

Frequently Asked Questions!

- Standard ovens : These ovens are designed for general drying and sterilization tasks, operating in a temperature range of 50°C to 300°C.

- Vacuum ovens : These ovens combine heating with vacuum technology to remove moisture and accelerate drying processes.

- Precision ovens : These ovens offer precise temperature control and stability, making them suitable for critical applications like material testing and semiconductor manufacturing.

- Drying laboratory glassware and equipment

- Sterilizing laboratory tools and materials

- Performing humidity and moisture content tests

- Incubating cultures and specimens

- Durable stainless steel construction

- Precise temperature control and monitoring

- Uniform air circulation for consistent results

- Safety features like emergency stop switches and overheating protection

- Efficient and controlled drying process

- Ability to handle a wide range of materials

- Reproducible results and consistent quality

- Reduced risk of contamination or damage to samples

- Size and capacity to accommodate your sample load

- Required temperature range and temperature control accuracy

- Specific features and functionality needed for your applications

- Safety and compliance with relevant standards

- High-quality, reliable equipment backed by extensive experience

- A comprehensive range of hot air ovens to suit diverse applications

- Expert technical support and after-sales service

- Competitive pricing and value for your investment